In the world of industrial infrastructure, few marvels stand as tall and elegant as cooling towers. These towering structures, often seen as the iconic silhouette on industrial landscapes, play a crucial role in maintaining the optimal operating برج خنک کننده for a variety of processes, most notably in power plants and manufacturing facilities. Let’s delve into the fascinating world of cooling towers, exploring their function, types, and environmental impact.

The Function of Cooling Towers:

At their core, cooling towers serve a simple yet vital function: they dissipate heat from industrial processes by transferring it to the atmosphere. Many industrial processes, such as power generation and manufacturing, generate significant amounts of heat. If left unchecked, this excess heat can damage equipment and disrupt operations. Cooling towers provide an efficient solution by using evaporation to remove heat from the process water.

How Cooling Towers Work:

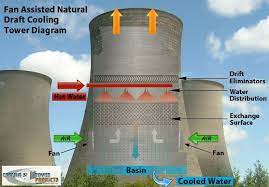

Cooling towers work on the principle of evaporative cooling. Hot water from industrial processes is circulated through the tower and distributed over a fill material, which increases the surface area for evaporation. As the water cascades down through the fill material, it is exposed to air moving upwards through the tower. This airflow causes a portion of the water to evaporate, absorbing heat in the process. The cooled water is then collected at the bottom of the tower and recirculated back to the industrial process, while the warm, moist air is released into the atmosphere.

Types of Cooling Towers:

Cooling towers come in various designs, each tailored to specific applications and operating conditions. The two primary types of cooling towers are:

- Natural Draft Cooling Towers: These towers rely on the buoyancy of hot air to create a natural airflow. They are characterized by their large, hyperbolic shape, which allows hot air to rise and escape while drawing in cooler air from the surroundings. Natural draft cooling towers are typically used in large power plants and industrial facilities where high cooling capacities are required.

- Mechanical Draft Cooling Towers: In contrast to natural draft towers, mechanical draft towers use fans or blowers to create airflow through the tower. This design offers greater control over airflow rates and is often more suitable for smaller-scale applications or locations with space constraints.

Within these two broad categories, cooling towers can further be classified based on their specific configuration, such as crossflow or counterflow, and construction materials, including concrete, steel, or fiberglass.

Environmental Considerations:

While cooling towers play a vital role in maintaining industrial processes, they also have environmental implications. One significant concern is the potential for water consumption and the discharge of warm water into water bodies, which can disrupt aquatic ecosystems. Additionally, the release of warm, moist air from cooling towers can contribute to localized weather phenomena, such as fog formation, known as “plume effect.”

To mitigate these environmental impacts, modern cooling tower designs often incorporate water-saving technologies, such as closed-loop systems that minimize water consumption by recycling process water. Additionally, advanced cooling tower designs focus on optimizing airflow to minimize the release of warm air into the environment.

Conclusion:

Cooling towers are not just towering structures on the industrial skyline; they are essential components of modern industrial processes, ensuring efficient heat dissipation and the smooth operation of critical systems. As industries continue to evolve and demand for cooling solutions grows, the development of innovative cooling tower technologies will play a crucial role in balancing industrial needs with environmental sustainability. By embracing advancements in design and operation, cooling towers will continue to be indispensable assets in the global industrial landscape, keeping the world cool while minimizing their environmental footprint.